When it comes to industries like construction, engineering, or industrial design, finding reliable custom metal fabricators is key to ensuring the success of your projects. Custom metal fabrication plays a pivotal role in creating components that are crucial for everything from machinery to structural components. In this article, you’ll learn everything you need to know about custom metal fabricators, from choosing the right one to understanding how their services can improve your project outcomes.

What Are Custom Metal Fabricators?

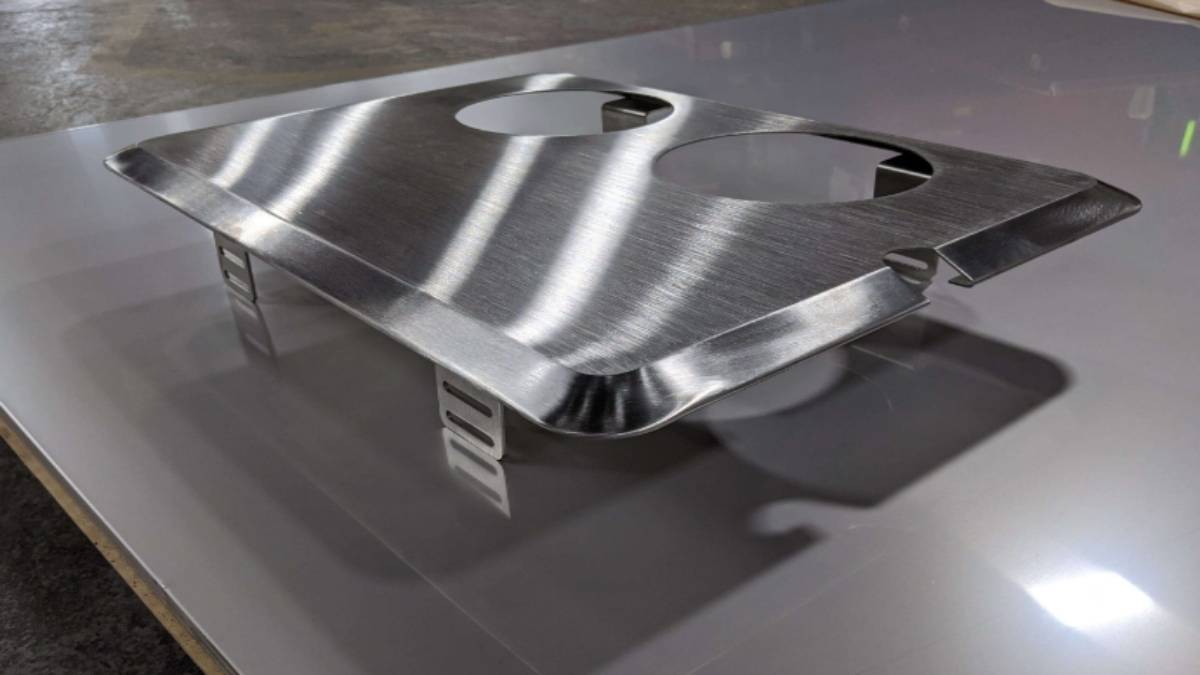

Custom metal fabricators are companies that specialize in the creation of metal structures, components, or products tailored to meet specific project requirements. Unlike mass-produced metal products, custom metal fabrication involves precise measurements, cutting, welding, and assembling metal parts according to individual specifications.

This process is used to create both small and large-scale products across a wide variety of industries, including automotive, construction, aerospace, and even artwork. The goal of custom metal fabricators is to offer solutions that standard off-the-shelf products cannot fulfill.

Why Do You Need Custom Metal Fabricators?

Choosing the right custom metal fabricator is crucial for ensuring that the metal components you need are not only accurate but also durable and of high quality. Some reasons to consider custom metal fabrication include:

-

Tailored Designs: Custom fabricators can work with unique specifications, ensuring your components meet exact needs.

-

Enhanced Durability: High-quality metal materials and precision manufacturing result in long-lasting components.

-

Flexibility: Whether you need a one-off product or a production run, custom fabricators can accommodate a variety of quantities.

-

Cost Efficiency: In some cases, custom metal fabrication can be more cost-effective compared to ordering pre-made parts, especially when considering quality and longevity.

Key Services Offered by Custom Metal Fabricators

Custom metal fabricators offer a wide range of services to meet the needs of different industries. Here are some of the core services you can expect:

1. Metal Cutting

Cutting is one of the most fundamental processes in metal fabrication. Custom metal fabricators use several cutting techniques such as laser cutting, waterjet cutting, or plasma cutting to ensure precise cuts on various types of metals.

2. Welding and Joining

Welding is essential for joining metal parts together. Depending on the project requirements, fabricators may use methods like MIG welding, TIG welding, or spot welding to create strong and durable joints.

3. Bending and Forming

This process involves bending and shaping metal into specific angles or shapes, often using presses or rollers. Custom metal fabricators can create complex bends and shapes to suit various structural or aesthetic needs.

4. Machining

Machining involves removing material from a workpiece using a cutting tool to achieve specific shapes or dimensions. Fabricators may use CNC (Computer Numerical Control) machines for precise and automated machining.

5. Metal Finishing

Once the metal parts are fabricated, finishing processes such as powder coating, galvanizing, or polishing are applied to enhance the appearance and protect against corrosion.

How to Choose the Right Custom Metal Fabricator for Your Project

Selecting the right custom metal fabricator is a decision that requires careful consideration. Here are some factors to keep in mind:

Experience and Expertise

Look for custom metal fabricators with a proven track record of completing projects similar to yours. The more experience they have, the better they’ll be at handling complex requirements and ensuring high-quality results.

Capabilities and Equipment

Ensure the fabricator has the necessary equipment to handle your project. Whether it’s laser cutting or CNC machining, having up-to-date technology is crucial for achieving precision and quality.

Material Expertise

Different projects require different materials. A skilled fabricator will know how to work with various metals, including steel, aluminum, and specialty alloys. Be sure they have experience with the material you intend to use.

Cost and Timeliness

While quality is important, cost and time efficiency are also factors to consider. Ask for quotes and timelines to make sure they align with your budget and schedule.

Industries That Benefit from Custom Metal Fabricators

Custom metal fabrication serves a broad spectrum of industries. Some of the most common ones include:

-

Construction and Architecture: Custom metal fabricators can provide structural components for buildings, bridges, and other infrastructure.

-

Automotive and Aerospace: Precision components for vehicles and aircraft can be fabricated for better performance and safety.

-

Energy and Utilities: Fabricators play an important role in creating parts for power plants, renewable energy sources, and pipelines.

-

Marine: Custom metal fabricators can create metal products designed for harsh marine environments.

The Benefits of Working with Custom Metal Fabricators

Precision and Quality

With custom metal fabrication, you can achieve precise measurements and high-quality results. Whether you’re creating a large structural part or a small machine component, precision is key to performance.

Flexibility in Design

Unlike mass-produced components, custom fabricators allow you to make adjustments throughout the design and manufacturing process, ensuring your project is executed exactly as you envision it.

Innovation

Custom fabricators are often at the forefront of innovation, providing creative solutions to design challenges. Whether it’s improving a component’s strength or optimizing a part’s performance, these fabricators are experts at adapting to new technologies and trends.

Conclusion: Choosing Custom Metal Fabricators for Your Next Project

Choosing custom metal fabricators is an important decision for any engineer or construction professional. Their ability to provide tailored, high-quality solutions can make a significant impact on the success of your project. Whether you’re designing a complex structure or need specialized components, custom metal fabrication offers unmatched precision and flexibility.

By considering the factors outlined in this article, you can ensure that you select a fabricator that aligns with your needs. Whether it’s quality, experience, or cost, finding the right partner for your custom metal fabrication project is key to ensuring your project’s success.

Frequently Asked Questions (FAQs)

1. What materials do custom metal fabricators work with?

Custom metal fabricators work with a wide range of materials, including steel, aluminum, copper, stainless steel, and specialty alloys. The choice of material depends on your project’s requirements.

2. How long does the custom metal fabrication process take?

The timeline for custom metal fabrication varies depending on the complexity of the project, the materials used, and the availability of equipment. On average, projects can take anywhere from a few days to several weeks.

3. What is the cost of custom metal fabrication?

The cost of custom metal fabrication depends on factors such as the material, complexity of the design, and production volume. It’s important to request quotes from multiple fabricators to get the best value for your project.

4. Can custom metal fabricators handle small-scale orders?

Yes, many custom metal fabricators offer services for both small-scale and large-scale production. Whether you need a single prototype or a batch of components, fabricators can accommodate your needs.

5. What are the advantages of CNC machining in metal fabrication?

CNC machining allows for high precision and repeatability in metal fabrication. It ensures that parts are made to exact specifications, making it ideal for projects that require consistent quality.

6. How do custom metal fabricators ensure quality?

Custom metal fabricators ensure quality through precise measurements, advanced manufacturing processes, and quality control checks at every stage of production. They also use high-quality materials to ensure durability and performance.